Dynamic Weighing Applications

Conveyor weighing system

Online check weighers

Belt weighing systems

In Motion weighing systems

Weigh feeders

Conveyor weighing machines

The Conveyor Machines are used to measure the flow rate of Bulky materials transported on a belt conveyor. This flow rate is received as a product of Belt Load & Belt Speed and integrated over time to derive the Total material delivered over the Conveyer.

Conveyor weighing system operate while the conveyor is in motion and are intended for the weighing of individual cartons, boxes, cans or -unpackaged products such as large cuts of meat. Our conveyor weighing system integrate into any industrial process that needs to weigh items as they pass through which is suited to checkweighing, straight weighing and weight accumulation operations.

This industrial scale system is made up of the Weigh Leg frame, which incorporates the weight sensors, a weight indicator, a photo eye kit (necessary for in motion weighing) and conveyor sections. When installed, the conveyor scale adds accurate and reliable weighing to new or existing production lines.

Features

Compact and smooth transmission

Maintenance-friendly

Reliable performance, long life

Fully integrated conveyor weighing system

Suitable for a wide variety of applications

Custom designed to fit your application requirements

Online check weighers

It is suitable to check weight of various product, over or less weight will be rejected out, qualify bags will be passed to next equipment. Online Checkweigher is most suitable for weighing of Cartons, Packet,Bottles,Pouches it is suitable for foods & Pharma Industries and Automative Industries.

Its simplified, modular design offers the ruggedness and durability for demanding production environments at significant savings, with no compromise in accuracy or weighing reliability.

Weigh and Seal range of online Checkweighers is designed and developed after extensive market study and offers multiple models to choose from depending upon the application specific details.

These systems are extremely efficient in ensuring outbound of only those products that meet the set target Weight and reject out all other Underweight or Over Weight packets.

The sorting out of Not OK Parts from OK parts not only ensures high batch Quality standards but also save tremendously on material cost by curbing over filled packets to move out.

Features

Two or three way classification(underweight / over weight / proper weight)

HACCP compatible structure prevents dust accumulation

High rigid structure allowing safe and precise weighing, with high speed weighing

Wide range of rejectors

Easy-to-see large 10.4 inch TFT screen prevents improper operation

Automatically checks for abnormal state of machine

Auto-sensitivity calibration function automatically calibrates sensitivity using built-in weight

Operation history, alarm history and calibration history are automatically recorded

Belt weighing systems

Belt weighing system is used for moving bulk materials in process industries. A belt weighing system consists of 3 elements: the weigh frame, which measures instantaneous mass, a tacho which measures belt speed, and the belt weigher electronics which integrates both these inputs to determine flow rate and totalised weight.

Since weight remains as the most reliable index of material accounting and can be measured directly and precisely, designers can offer accurate weighing systems to maintain higher accuracy and better accountability in the process.

Belt weighers also known as belt weighing scales are equipments that measures the quantity of material that has been conveyed by a belt.

A belt weighing system consists of 3 elements: the weigh frame, which measures instantaneous mass, a tacho which measures belt speed, and the belt weigher electronics which integrates both these inputs to determine flow rate and totalised weight.

The weight of the material transported is determined by weighing the belt load and measuring the belt speed.

The belt speed remains constant while the feed rate is regulated by varying the belt loading if required. Alternatively the conveyor belt can be stopped after a pre-defined volume X has been transported (for example when batching at loading stations).

We are offering to our clients high quality Electronic Belt weighing system which are made by using advance technology and superior grade raw material. These are quality checked at each stage of production to ensure flawless range. Our range is highly powerful indicator which integrates more control in your process than any other system.

Features

Advance technology

Best performance

Higher accuracy is achieved as the system uses straingauge type precision loadcell which have negligible deflection

Digital Proximity speed sensor designed to generate sufficient pulses even at very low belt speed

High Speed ADC is used to have faster response

Self diagnostic facilities

Unique zero tracking software to compensate for varying “weight of the belt”

Remote display – communication port available as an option

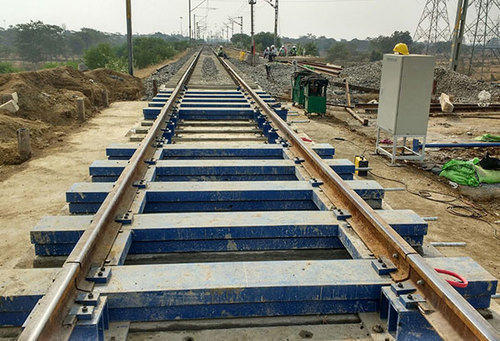

In Motion Weighing Systems

A Rail Weigh-bridge is a weighing instrument used for weighing loaded rail wagons. It has a load receptor, inclusive of rails for conveying railway vehicles. It is designed to record the weight of all wagons individually and collectively excluding the weights of engine and supportive wagons. The weighing may be done in motion or in static position.

Weigh and seal provide superior quality rail weighing systems, automatic weighing systems that are based on latest technology. Our Railway weigh bridge weighing system is designed in accordance with the worldwide requirement RAILWAYS/RDSO.

The system design is very simple yet powerful, allow you to install the system in short span even at a very narrow curved line. The system has been designed with new and simple algorithm to deduct complex engine and wagon’s track pattern.

The improved Rail Sensor design allow our combo rail fit for even short span of Straight Line requirement even less than 45Mts. The user will get wide choice for the software, inter connectivity via Ethernet, GMS, USB. The system can be simple Pit and Pitless design.

The in-motion rail scale is a pit mounted rail weighbridge, designed to provide rail wagon weights and train weights quickly, affordably and safely while in transit at a steady speed.

This dynamic train weighing scale consists of a fabricated steel deck supported on load cells, which provide in-motion weighing of wagons up to 120 tonnes gross.

Benefits

It has a Pitless design with minimum excavation

It has Low cost on Installation

High accuracy Weighing electronics Proximity with Track Switches

It also have Over speed signal with an Audio / Visual / Print out

It also aids in Rollback detection

All types of 4 axle/ 2 axle railway and other wagon Weighment

All types of Loco removal

Auto / Manual Operation

Report creation Rakewise, Daily, Periodically

Weighing feeders

A weigh feeder is conveying and weighing at the same time.

A special type flow meter suited for powdered or granular solids is the weigh feeder. One of the most common weigh feeder designs consists of a conveyor belt with a section supported by rollers coupled to one or more load cells, such that a fixed length of the belt is continuously weighed.

Weigh and seal Weigh feeders are custom engineered to meet all of our customers’ needs with the latest technology, bolstering efficiency, improving accuracy and ensuring long-term reliability.

There are two types of belt weighfeeders: those with a controlled belt speed and those with a metering hopper.

Belt weighfeeder with controlled belt speed:

Belt weighfeeders with controlled belt speed are belt-assisted feeders whose belt speed is adapted so it attains the nominal delivery rate.

Since the same amount of material is not always transported on the conveyor belt, the belt speed must be varied to achieve a constant feed rate per unit of time. The weight of the material transported is determined by weighing the belt load and measuring the belt speed.

Depending on design, belt weighfeeders have delivery rates ranging from several kilograms to several hundred tons an hour.

Belt weighfeeder with metering hopper:

Belt weighfeeders with metering hoppers have a controlled feeder which adjusts the amount of material on the belt.

These metering hoppers, which may be chutes, augers, radial vane rotors or conveyor belts, feed precisely the right amount of material to the conveyor belt.

Belt weighfeeders are suited to bulk materials which flow easily and don’t stick to the belt and can handle very large mass flows.

Features

Fully automatic zero and span calibration

Highly reliable 32 bit microprocessor based controller

Highly precise vibrating wire load cell with resolution of 1:1,000,000

No calibration required in case of digital load cell

In case of analog load cell simple calibration with static loads or by electronic calibration

Can be operated from any location viz: local panel, main panel or control room

Precision machined rollers used in weigh zone for achieving high accuracy

Rubber lagged crowned pulley is used to avoid belt slip

Digital speed sensor mounted on non drive pulley shaft to sense the actual belt speed

Rigid heavy duty construction