Electronic Weighing Bridges

Weigh bridges are weighing machines dedicated to weighing large industrial vehicles and their contents, usually for commercial purposes. Historically, Weigh bridges were originally designed to be installed over a pit with housed levers and other mechanical components which was allowed for the weighing platform to be connected to a balancing mechanism which was used to ascertain the vehicle’s weight.

However, this construction proved to be limiting due to the separation between the Weigh bridge platform and its balancing element. Later developments have seen the implementation of load cells into Weigh bridges, allowing for the creation a wholly self-contained unit.

A truck to be weighed is directly driven to the platform of a Weigh bridge and hence, the platform is subjected to the entire load and vibrations created by a moving truck. Our Weigh bridge platforms (made of steel) are designed very carefully to withstand these loads without damage and is highly durable. The girders and plates used in our platform are selected very carefully and undergoes stringent quality checks.

Furthermore, the transducer portion of a load cell provides a digital readout of the vehicle’s weight which is more accurate than the now-archaic methods used in the past.

The use of modern machines also affords operators the ability to monitor a Weigh bridge’s performance from a separate location. Remote operation provides added safety for staff working with Weigh bridges and also offers flexibility to companies installing them on a more permanent basis.

Weigh bridge Software

We provide the best Weigh bridge management software for all industries which allows data to be easily stored, transferred and repurposed.

Software can be used to automate many of the processes associated with Weigh bridge data collection and this increases the efficiency of vehicle weighing. This is beneficial to the company and customer, as the overall time spent using the Weigh bridge (including the issuing of a ticket/receipt) is greatly reduced.

For companies, another advantage to using Weigh bridge software is its ability to integrate with existing databases. This feature helps in the creation of reports used to identify potential issues as well as to support the creation of financial forecasts and other business projections.

Applications

Weigh bridges are used for legal-for-trade freight weighing of road vehicles or for loading goods on the scales.(e.g. Bulk cargo). Weigh bridges are typically used to identify the weight of industrial vehicles and, simultaneously, the weight of their contents. Many goods are often sold by weight and Weigh bridges are therefore the ideal solution for performing quick continuous vehicle measurements to record these metrics.

Pit Type Weigh Bridge

Weigh and seal system services provides (pit type steel deck Weigh bridge) fully electronic truck scales series are new generation products with good points of multi-structure truck scales. The Electronic Static Weigh-bridge is made up of a framework of girders adequately reinforced with transverse beams and suitable non-slip top deck with Pit type Structure. They have been tested with heavy-load for a long time and are optimized gradually. Their main beams and auxiliary beams are made of rigid section-steels like I-steel. High quality steel plates are selected and used for its platform, and its scale body is reasonably pieced into separate parts. While welding, we use the special technique and clamps, precision measure technology of space positioning and advanced weld-technique, so as to ensure the level degree of large area, the space geometry-dimension and the rational distribution of weld stress.

This type of Weigh bridge is most suitable for places with limited space e.g. non-hilly areas where the construction of pit is not a costly affair. Since the platform is in level with the ground, vehicles can approach the Weigh bridge from any direction.

Benefits

Lesser Space Required (As it has no ramps)

Rickshaws & Tractor Trolleys can also be weighed as platform is in flush with ground Level.

No Ramp require for turck movement because it is installed in land surface level

Costly Foundation

Pitless type Weigh Bridge

Pitless type of Weigh bridge / Truck scale with sturdy and strong mild steel platform is most suitable where the excavation work for foundation is difficult or construction of pit is expensive. Since the structure is above ground level, vehicles can approach the Weigh bridge only from two directions where the ramps are provided and so no high water table or drainage problem. In Pitless Type Weigh bridge RCC ramp work must be required at least 3 meters for both sides for easy movement of vehicle.

Pit less Weigh bridge has some unique benefits over other types of Weigh bridges.

Benefits

Designed for heavy weighing & harsh environment

Each & Every parts are dismantle for easy transportation and installation

Economically and easily maintained and service as entire deck is mounted above the ground level

Platform above ground level- No water logging during rainy season

Problem of pit maintenance is eliminated

Easy maintenance since all parts accessible above ground level.

Ribs are welded continuously across I-beam which ensures extra strength to Weigh bridge deck.

On board weighing bridge

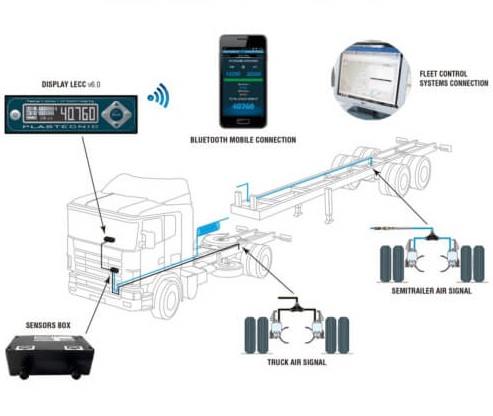

Based on constant development and technology improvements, applications for on-board weighing bridges are rapidly expanding. On-board scales are found in almost every trucking industry, such as dirt & aggregate hauling, construction & demolition, refuse, agriculture, mining, and bulk hauling. Given the high cost of time and equipment, on-board weigh bridges are having a dramatic impact on the efficiency and profitability of operating a truck.

Weigh and seal on board weighing bridge is the best one in accuracy and repeatability. The system works on the principle of that the strain gauge pasted on the axle sensor, bending for acting axle is sensed by our axle sensor and weight is calculated. The low level signal from the axle sensor is amplified and filtered by the high precision monolithic A/D converter and converted into Digital format. The digitized data is being further processed and store according to the customer need and application.

On Board Weighing System for Wheel Loaders / On Board Dumper Weighing System (GUARD–53) consists of a very high capacity pressure transducer fixed to the inlet port of the vehicle's lifting cylinder. The hydraulic pressure in the lifting cylinder is proportional to the load carried in the bucket.

The output of the pressure transducer is connected to our Indicator which is mounted inside the operator’s cabin. This Indicator works on 24V DC. The Indicator displays the instantaneous weight of material in the bucket and also totalizes this weight reading.

This totalized quantity is subtracted from the target load which is set by the operator. This allows the operator to control the quantity of material into the truck or wagon in the final stages of loading, thereby avoiding over-loads.

Features

Most effective on-board weighing system for wheel loaders.

Direct display of material loaded into trucks / wagons.

Saves time and fuel, on load correction re-runs by trucks.

Saves money on wagon over-loading, by effective load monitoring.

Prevents over-loading / under-loading into trucks / wagons.

No compromise on loader operation or speed.

Easy to operate, wide screen and large display console, with touch screen.

Quick data transfer from loader weighing module to pc with an ordinary pen drive.

Data can be analyzed, date wise or truck wise or material wise etc.

Installation in 5 hours, including calibration.

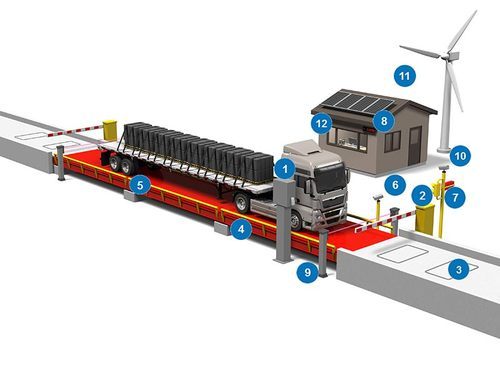

Unmanned Weigh bridge System

Weigh and seal is leading service provider for Unmanned Weigh bridge systems. Unmanned Weigh bridge Systems are a stand-alone system which allows 24/7 weighing operations without the need of an operator. With the use of system's user-friendly interface, it can be totally operated by the truck driver which in turn less operational cost and high efficiency in the entire process.

Unmanned Weigh bridge systems are designed to manage and track the critical information created at the time of weighing and label products in an easy and flexible manner. As drivers are not required to physically leave their vehicle during the weighing process, unmanned Weigh bridge systems are an ideal tool to improve business efficiency, driver turnaround time and health as safety on site. The console guides the driver through the weighing process via a series of on-screen prompts, collecting and storing vehicle and weight data, then transferring it directly into your Weigh bridge operator system.

Benefits

Weigh and seal driver operated consoles (DOC) provide Weigh bridge owners the flexibility of running an unmanned Weigh bridge system.

Ideal for 24 hour operations.

The DOCs keep your Weigh bridge running smoothly without a dedicated Weigh bridge operator.

Low operational costs.

User friendly.